Increased productivity, lower PC costs

An Ethernet-based “smart” controller, the LEC-3.1 is designed to operate as a standalone unit within a galvanometer-based laser scanning system.

The LEC-3.1’s intelligence allows you to control the unit over a LAN (Local Area Network), and store and execute jobs locally or in stand-alone mode, eliminating the need for local computer control. This function translates into maximum flexibility for equipment location, increased productivity, and lower PC costs.

The LEC-3.1 is specifically optimized for WinLase LAN Software. In addition, Lanmark Controls offers I/O modules that simplify access to connections on the LEC-3.1 control board.

The LEC-3.1 is an electrically compatible replacement for the LEC-1 and EC-1000.

Key Benefits

- Improved productivity. Enables remote access, control, and monitoring

- Simplified management. One board controls multiple laser systems; local execution and streaming modes fit customer automation requirements

- Three configurations. Basic (requires a PC), Standard (adds stand-alone capabilities), Advanced (adds mark-on-the-fly capabilities)

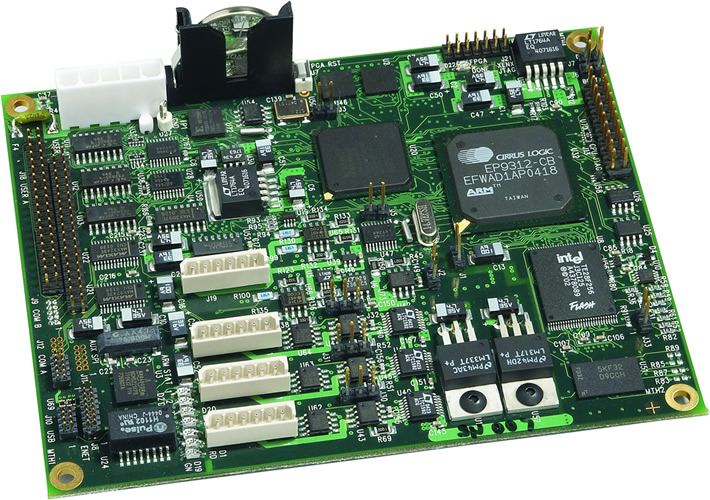

Hardware Highlights

- 10/100 Ethernet-based controller

- Leading-edge dual processor architecture

- ARM processor to handle 10/100 Base-T Ethernet communication and system software

- FPGA/SoC (System-on-a-Chip) for on-board real-time processing of vectors and laser control

- 1Ghz CPU for overall fast connection experience

- 512MB on-board FLASH storage for local jobs

- 512MB on-board RAM to execute large job files

- Complete independent control over all laser output signals